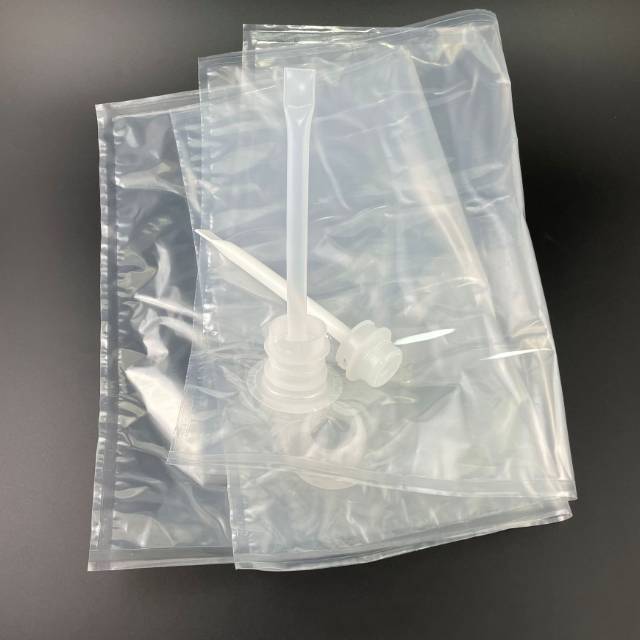

Factory 3L 5L 10L 15L Bag In Box For Milk Dairy Products Packaging

- EXW Price:USD0.1~USD0.8 (Depends on the mateials,size and quantity)

- Size: As size standard or customization

- Capacity:3L 5L 10L 15L 20L,customization

- MOQ:5000pcs

- Free samples (1~2 pcs samples are free)

- Materials: NY/VMPET/PE+PE,NY/PE+PE,EVOH+PE

- Temperature:-20 ° C ~ +85° C

- Lead Time: 21 days after payment confirmed

- Price Term:DDP,CNF,EXW,CIF,etc.

- Payment: T/T, Visa,paypal,alibaba,etc.

Welcome to send inquiry for more milk dairy bag in box packaging details.

Materials:

- NY/PE+PE

- EVOH+PE

- NY/VMPET/PE+PE

- Silicone tube

Product Process:

Blown Film/Laminate materials/Making bags/Pakaging

Industrial use

- Food:Vinegar,Condimentsd,Sauces,Edible oil,Liquid egg,Jam,etc.

- Beuerage:Coffee&Tea,Dairy&Milk,Juice,Smoothies, Spirits, Water,Wine,Soft drinks.

- Non-food:Agricaltural chemicals,Automotive fluids,Beautye&Personal care,Cleanip,Chemicals.

Feature:

- Excellent barrier performance for liquid food

- Environmentally low carbon effectiveness, fully compliant with new environmental regulations

- Cost-effective solution compared to traditional packaging such as can, hard containers.

- Compliant with food packaging regulations

- Re-closable with cap

- Reduce packaging and transportation cost, easy storage

- Strong sealing strength, non-breakage, non leakage

- Strong sealing strength, non-breakage, non leakage

Key advantages

- The bag and tap work together to prolong the shelf life before and after the pack is opened.

- Bag-in-Box packaging is supplied flat to maximise storage space and minimise transport costs.

- Each bag is specifically constructed to preserve the exact liquid inside, ensuring the contents stay uncontaminated by the air outside.

- Environmentally friendly – lower carbon footprint than plastic or glass alternatives

Bag In Box is a sustainable choice of packaging for many industries such as wine, juice, liquid eggs, dairy and also non-food applications such as motor oil and chemicals. For more details, pls send inquiry to us!

Hot Products

Bag-in-box packaging utilizes a box, bag, and fitment to transport and dispense liquid products both efficiently and without contamination.

1,Bag: The bag is constructed from layers of film that are sealed together and designed to protect the product quality and keep it safe inside from filling through end use.

2,Spout: The foundation of our all bag-in-box fitments, this plastic-framed opening is sealed into the bag when it’s made and is the entry point for filling the product into the bag. After filling, bag spouts are covered by either a simple cap, dispensing tap, or connector and fitment depending on their intended end-use.

3, Fitment: This is a broader category of items including spouts, caps, valves, and more. It encompasses anything that attaches to the bag spout. Bag-in-box fitments can be anything from simple caps that cover a spout, to sophisticated dispensing valves or connecters and hoses that bridge between the spout/valve and outside dispensing equipment.

4,Box: the outer package that holds the capped and filled bag. This can be anything from a simple cardboard box to an industrial-sized steel drum.